HYDRAULIC HOSES

High pressure hose

Divider is here

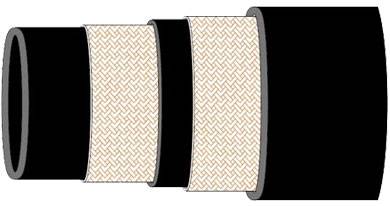

Flexotech supplies a range of high-pressure hoses for various industries. Our high-pressure hoses are fabricated with an inner core of thermoplastic material, with several layers of reinforcement high-tensile steel wires and wear-resistant outer covering. As a result, high-pressure hydraulic hoses are an ideal choice for hydraulic applications.

The high-pressure hydraulic hoses are made to bear extreme physical conditions and ensure a safe movement of liquids or gases. In addition, our high-pressure hoses come with excellent chemical resistance properties; the friction is minimal to ensure a swift flow and a low permeation level ideal for gas and oil applications.

High-pressure hydraulic hoses are ideal for transporting mineral and hydraulic fuel, fuel oil and water-oil emulsions, road construction, agriculture, mining and oil and gas industries.

Rubber Hose

+ Hydraulic Hose

Parker High Pressure Hoses Manufacturers

Parker high pressure hose have become synonymous with quality and reliability in the realm of hydraulic systems. As one of the leading parker high pressure hose, Parker boasts an extensive range of hoses designed to meet the demanding needs of various industries. The EN 856 series, including 4SP, 4SH, R12, R13, and R15, showcases Parker’s commitment to providing durable and high-performance hydraulic solutions.

The EN 856 4SP hose is constructed with a core of CR synthetic rubber, reinforced with four spiral steel wires, and covered with CR synthetic rubber on the outside. This design results in a hose with superior abrasion resistance and impulse fatigue. It is ideal for oil field services, paving and road maintenance, automotive, construction, ground and building maintenance, ground support equipment, and material handling.

Similarly, the EN 856 4SH hose shares the same construction features, offering higher working pressure under the same temperature. This makes it suitable for various applications, including oil field services, paving and road maintenance, automotive, construction, ground and building maintenance, ground support equipment, and material handling.

Moving on to the EN 856 R12 hose, this hydraulic hose is tailored for High Pressure hoses in Bangalore hydraulic oil lines. The inner core resists oil and water, while the cover, made of high-quality synthetic rubber, provides resistance to abrasion, corrosion, weather, ozone, ageing, sunlight, and cuts. These properties make the EN 856 R12 hose ideal for mining, construction, oil field services, paving and road maintenance, ground and building maintenance, and automotive.

The EN 856 R13 hose follows a similar construction, featuring resistance to oil and water in its inner core and a robust cover made of high-quality synthetic rubber. With four or six spiral steel wires, this hose is suitable for high-pressure hydraulic oil lines and finds applications in construction, oil field services, paving and road maintenance, waste and refuse, and material handling equipment.

The EN 856 R15 hose’s construction includes a core of CR synthetic rubber reinforced with four or six high-tensile spiral steel wires. The outer cover, made of SBR synthetic rubber, enhances its resistance to abrasion, corrosion, weather, ozone, ageing, sunlight, and cuts. This versatile hose is employed in construction, oil field services, paving and road maintenance, ground and building maintenance, utility equipment, and machine tools.

Parker high-pressure hoses extend beyond the EN 856 series. The SUPER JACK HOSE, for instance, features a core of NBR synthetic rubber reinforced with two braids of steel wire and covered with SBR synthetic rubber. This hose is suitable for high-pressure hydraulic oil lines, making it widely used in hydraulic return and drain lines, transportation, utility equipment, construction, ground support equipment, and material handling.

Finally, the SPIRABLAST 40K HOSE, constructed with a CR synthetic rubber core reinforced with four high-tensile steel wire spirals and covered by SBR synthetic rubber, is designed for higher working pressure applications. With four layers of high-tensile spiral wire, this hose excels in abrasion resistance and impulse fatigue, making it suitable for water blast/jetting applications.

Flexotech, as a prominent player in the industry, recognizes the importance of high pressure hoses manufacturers in Bangalore and beyond. These hoses play a pivotal role in ensuring the efficiency and reliability of hydraulic systems across various sectors. As Flexotech continues to provide cutting-edge solutions in hydraulic applications, incorporating Parker’s high-pressure hoses solidifies its commitment to delivering quality products to its clientele.

Construction: CR – Synthetic rubber at the core reinforced with four spiral steel wire covered by CR synthetic rubber on the outside

Application:

These hose has higher working pressure under the same working temperature. Four layers of high tensile spiral wire give the hose best abrasion resistance and impulse fatigue. Therefore these hoses are used in Oil field services, paving and road maintenance, automotive, construction, ground and building maintenance, ground support equipment, material handling etc.

Inner Tube

CR – Synthetic rubber

Reinforcement

Four spiral steel wire

Cover

CR – synthetic rubber

Temp. Range

-40°F to +212°F (-40°C to +100°C)

Hose I.D Hose I.D |

Hose ROD Hose ROD |

Hose O.D Hose O.D |

Working Pressure Working Pressure |

Bend radius Bend radius

|

|||

|---|---|---|---|---|---|---|---|

| Inch | mm | mm | mm | Psi | Bar | mm | |

| 3/8 | 9.5 | 17.5 | 21.4 | 6500 | 450 | 180 | |

| 1/2 | 12.7 | 20.2 | 24.6 | 6000 | 420 | 230 | |

| 5/8 | 15.9 | 23.8 | 28.0 | 5000 | 350 | 250 | |

| 3/4 | 19.0 | 28.2 | 32.0 | 5000 | 350 | 300 | |

| 1 | 25.4 | 35.3 | 39.5 | 4000 | 280 | 340 | |

Construction: CR Synthetic rubber at the core reinforced with four spiral steel wire covered by CR synthetic rubber on the outside

Application:

These hose has higher working pressure under the same working temperature. Four layers of high tensile spiral wire give the hose best abrasion resistance and impulse fatigue. Therefore these hoses are used in Oil field services, paving and road maintenance, automotive, construction, ground and building maintenance, ground support equipment, material handling etc.

Inner Tube

CR – Synthetic rubber

Reinforcement

Four spiral steel wire

Cover

CR – synthetic rubber

Temp. Range

-40°F to +212°F (-40°C to +100°C)

Hose I.D Hose I.D |

Hose ROD Hose ROD |

Hose O.D Hose O.D |

Working Pressure Working Pressure |

Bend radius Bend radius

|

|||

|---|---|---|---|---|---|---|---|

| Inch | mm | mm | mm | Psi | Bar | mm | |

| 3/4 | 19.0 | 28.4 | 32.0 | 6000 | 420 | 280 | |

| 1 | 25.4 | 35.2 | 39.0 | 5500 | 380 | 340 | |

| 1-1/4 | 31.8 | 41.9 | 45.3 | 4700 | 325 | 460 | |

| 1-1/2 | 38.1 | 48.8 | 53.3 | 4200 | 290 | 560 | |

| 2 | 50.8 | 63.2 | 68.0 | 3600 | 250 | 700 | |

Construction: CR Synthetic rubber at the core reinforced with four spiral steel wire covered by CR synthetic rubber on the outside

Application:

These hoses are suitable for high pressure hydraulic oil lines. The inner core is resistant to oil and water. The cover is made of high quality synthetic rubber, making it resistant to abrasion, corrosion, weather, ozone, aging, sunlight and cut. Therefore these hoses are used in mining, construction, Oil field service, paving and road maintenance, grounds and building maintenance, automotive etc.

Inner Tube

CR – Synthetic rubber

Reinforcement

Four spiral steel wire

Cover

CR – synthetic rubber

Temp. Range

-40°F to +257°F (-40°C to +125°C)

Hose I.D Hose I.D |

Hose ROD Hose ROD |

Hose O.D Hose O.D |

Working Pressure Working Pressure |

Bend radius Bend radius

|

|||

|---|---|---|---|---|---|---|---|

| Inch | mm | mm | mm | Psi | Bar | mm | |

| 3/8 | 9.5 | 17.2 | 20.0 | 4000 | 280 | 65 | |

| 1/2 | 12.7 | 20.7 | 24.0 | 4000 | 280 | 90 | |

| 5/8 | 15.9 | 24.6 | 27.2 | 4000 | 280 | 100 | |

| 3/4 | 19.0 | 27.7 | 30.5 | 4000 | 280 | 120 | |

| 1 | 25.4 | 34.9 | 38.0 | 4000 | 280 | 150 | |

| 1-1/4 | 31.8 | 43.9 | 46.2 | 3000 | 210 | 210 | |

| 1-1/2 | 38.1 | 50.4 | 53.3 | 2500 | 175 | 250 | |

| 2 | 50.8 | 63.6 | 65.9 | 2500 | 175 | 635 | |

Construction: CR Synthetic rubber at the core reinforced with four or six spiral steel wire covered by CR synthetic rubber on the outside

Application:

These hoses are suitable for high pressure hydraulic oil lines. The inner core is resistant to oil and water. The cover is made of high quality synthetic rubber, making it resistant to abrasion, corrosion, weather, ozone, aging, sunlight and cut. Therefore these hoses are used in construction, Oil field service, paving and road maintenance, waste and refuse, material handling equipments etc.

Inner Tube

CR – Synthetic rubber

Reinforcement

Four or six spiral steel wire

Cover

CR – synthetic rubber

Temp. Range

-40°F to +257°F (-40°C to +125°C)

Hose I.D Hose I.D |

Hose ROD Hose ROD |

Hose O.D Hose O.D |

Working Pressure Working Pressure |

Bend radius Bend radius

|

|||

|---|---|---|---|---|---|---|---|

| Inch | mm | mm | mm | Psi | Bar | mm | |

| 3/4 | 19.0 | 29.0 | 31.9 | 5000 | 350 | 240 | |

| 1 | 25.4 | 35.6 | 38.5 | 5000 | 350 | 300 | |

| 1-1/4 | 31.8 | 46.8 | 50.0 | 5000 | 350 | 420 | |

| 1-1/2 | 38.1 | 54.3 | 57.6 | 5000 | 350 | 500 | |

| 2 | 50.8 | 68.1 | 70.9 | 5000 | 350 | 640 | |

Construction: CR Synthetic rubber at the core reinforced with four or six high tensile spiral steel wire covered by SBR synthetic rubber on the outside

Application:

These hoses are suitable for high pressure hydraulic oil lines. The inner core is resistant to oil and water. The cover is made of high quality synthetic rubber, making it resistant to abrasion, corrosion, weather, ozone, aging, sunlight and cut. Therefore these hoses are used in construction, Oil field service, paving and road maintenance, grounds and building maintenance, utility equipment, machine tool etc.

Inner Tube

CR – Synthetic rubber

Reinforcement

Four or six high tensile steel wire spirals

Cover

SBR – synthetic rubber

Temp. Range

-40°F to +257°F (-40°C to +125°C)

Hose I.D Hose I.D |

Hose ROD Hose ROD |

Hose O.D Hose O.D |

Working Pressure Working Pressure |

Bend radius Bend radius

|

|||

|---|---|---|---|---|---|---|---|

| Inch | mm | mm | mm | Psi | Bar | mm | |

| 3/4 | 19.0 | 28.4 | 32.0 | 6000 | 420 | 265 | |

| 1 | 25.4 | 35.2 | 38.5 | 6000 | 420 | 330 | |

| 1-1/4 | 31.8 | 46.8 | 49.6 | 6000 | 420 | 445 | |

| 1-1/2 | 38.1 | 54.3 | 57.1 | 6000 | 420 | 530 | |

Construction: NBR Synthetic rubber at the core reinforced with two braids of steel wire covered by SBR synthetic rubber on the outside

Application:

These hoses are suitable for high pressure hydraulic oil lines. The tube is made from high quality synthetic rubber making it highly suitable for oil delivery. The cover is made of high quality synthetic rubber, making it resistant to abrasion, corrosion, weather, sunlight, aging etc. Therefore these hoses are widely used in hydraulic return and drain lines, transportation, utility equipments, construction, ground support equipment, material handling etc,

Inner Tube

NBR – Synthetic rubber

Reinforcement

Two braids steel wire

Cover

SBR – synthetic rubber

Temp. Range

-40°F to +212°F (-40°C to +100°C)

Hose I.D Hose I.D |

Hose ROD Hose ROD |

Hose O.D Hose O.D |

Working Pressure Working Pressure |

Bend radius Bend radius

|

|||

|---|---|---|---|---|---|---|---|

| Inch | mm | mm | mm | Psi | Bar | mm | |

| 1/4 | 6.4 | 12.7 | 14.8 | 10000 | 690 | 102 | |

| 3/8 | 9.5 | 16.7 | 18.8 | 10000 | 690 | 127 | |

| 1/2 | 12.7 | 19.9 | 22.0 | 10000 | 690 | 180 | |

SPIRABLAST 40K HOSE

Construction: CR Synthetic rubber at the core reinforced with four high tensile steel wire spirals covered by SBR synthetic rubber on the outside

Application: These hose has higher working pressure. Four layers of high tensile spiral wire give the hose best abrasion resistance and impulse fatigue. Therefore these hoses are used in water blast/jetting etc.

Inner Tube

CR – Synthetic rubber

Reinforcement

Four high tensile steel wire spirals

Cover

SBR – synthetic rubber

Temp. Range

-40°F to +212°F (-40°C to +100°C)

Hose I.D Hose I.D |

Hose ROD Hose ROD |

Hose O.D Hose O.D |

Working Pressure Working Pressure |

Bend radius Bend radius

|

|||

|---|---|---|---|---|---|---|---|

| Inch | mm | mm | mm | Psi | Bar | mm | |

| 3/8 | 9.5 | 19.0 | 23.0 | 15950 | 1100 | 150 | |

| 1/2 | 12.7 | 23 | 27.0 | 15950 | 1100 | 230 | |

Widely Used in

We manufacture high quality products, using the latest technologies and

equipments to meet the most complex Industry requirements.